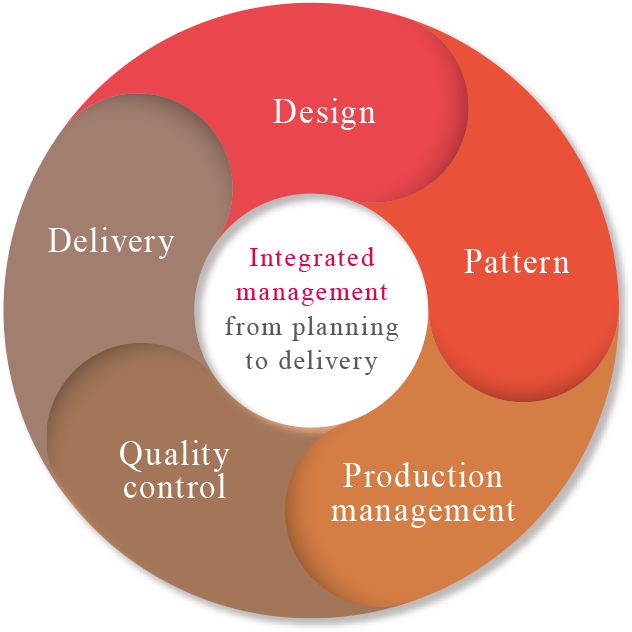

We manage the process of all work,

so the value of the underwear will increase.

It is mainly the underwear that is chosen by the end users.

The company has the market research and the planning and designing done, makes sure the plans are easily transmitted and has the underwear accurately completed, so massive amounts of patterns can be created.

It starts from the design, then choosing the material, making the patterns, creating the prototype, then sewing and producing. During this process, it is checked repeatedly and much of the underwear is being completed.

There are many companies that specialize in only design, pattern making, and sewing (production) or partially dividing some processes to specialized companies.

In order to make the best quality we make sure and manage the whole process of the work.

First, from “planning and design” to actualize “hit = high selling” to “pattern making”. Next, “production control” for estimation, ordering materials, and the deadline. Then, “quality control” for the sewing process by repeated critical checks for one process at a time based on the Japanese standard. The process of ordering and delivering are all managed, and all of the information is completed, so there will be no lags in delivery.

The process of the design is placed as the first operation, you can find the data for each of the processes in the database. All of the information about each of them in the database can be found about the designs and the delivery, so the upcoming steps for the rest of the process will move quickly and smoothly.

In order to make three-dimensional prototypes from two-dimensional drawings, specialized knowledge and precision is required to surpass pattern paper.

It is necessary to fully understand the purpose of the design and the ways that the material is cut and sewn, and how the image is completed and presented. In actuality when it becomes a product the silhouette and how it fits must be taken into consideration. Of course, how you choose the material and knowing the trend is important as well.

The designers, pattern makers, the staff in charge of sewing, and production management work together as a team. Usually the staff members never change. We always work with new information and make sure to avoid any malfunctions during the process of making the items. Working smoothly and having the trust of our customers is our priority. Although the information is shared within the company, we believe that we cannot relieve our clients if different members join the meeting every time.

In order to make popular bras, a massive amount of products of same quality will be required to meet the same high standards.

Whether the homogeneous product can be made for the requested amount, there is still the question of the ability of the OEM/ODM. We not only plan the designs the end users choose, but we preserve high quality products and think about the working procedures of the factories and build from there.

We design components of precision which can be simple, quick, and beautifully sewn.

Once the prototype is completed, the company requests us to attend the fitting and receive feedback from the customers.

We check if the technique and human engineering is created logically, and also see what the style really looks like before then deciding the necessary corrections. Upon completion we place the first order and sign GO.

It is not only the perspective from the creating side, but also the ideas of the corporations that sell the products and the opinions of the how the users actually use the product, that we take into consideration that the actuality of the fashion’s comfort since it is difficult to read the numbers that appear.

At our production site we do not only make the products that we are told to make.

When performing the line test for the prototypes or the products, whatever suggestions we receive, such as, “How about improving this part?” or “Maybe you should do it like this instead?” we let the designers know right away.

Every single person who is working on this process look for the best qualities, they never stop until their work is fully accomplished, they all work together to come to a final decision they can all agree on. It is an organization with people trying to build each other up to be a better unit.

Because it is an integrated production, there are many things we can do.

Shapes that have not developed from the abstract image, embodies the compatibility of the function of both fashion and trend.

We will offer our original designs that you may not find anywhere else.

We ensure to make the two-dimensional materials fit the three-dimensional bodies of our customers, and we would also like for the customers to feel comfortable in the materials.

Click here for more information.

We manage the material and when it is produced, we check it thoroughly and repeatedly maintain control of the quality. Thus ensuring what we offer to be top quality.

Click here for more information.We provide you with the service as the OEM/ODM manufacturer for female underwear including bras, camisole with bras, girdle, bodysuits, shorts, etc. by selecting particular materials and designs.